An Introduction to Process Mapping

Business process mapping is an essential tool used to design, document, communicate, and improve the flow of work within an organization. Process mapping aims to improve efficiency, lower costs, and improve customer satisfaction.

This article provides an overview of why process mapping is essential. It also outlines various business process mapping techniques that can get you on the path to process improvement.

What is Business Process Mapping?

Business Process Mapping is crucial to the Business Process Management (BPM) cycle.

It is used as part of Process Identification to create an As-Is, or current, visual representation of the business processs.

An up-to-date process map enables businesses to understand how their operations work and helps them identify areas of improvement, eliminate bottlenecks, and streamline operations.

Business Process Mapping uses flowcharts, diagrams, or other visual tools to clearly and concisely represent the process flow.

Why Business Process Mapping?

You would never consider heading out on an expedition without a map or building a house without a blueprint.

This analogy holds for process maps. A process map, and the associated process documentation, is an essential tool to guide a company towards a successful outcome.

There are numerous use cases for business process mapping. These include:

- In support of process identification and discovery

- Capturing the end-to-end flow of work within a company

- Showing the interaction between the company and its suppliers, customers, and other stakeholders

- Enabling process improvement and optimization

- Driving digital transformation by helping to identify Business Process Automation opportunities

- Supporting process audit, compliance, and governance activities

What is a Business Process?

No discussion on processes would be complete without first defining what a business process is.

A business process is a set of tasks that transform inputs into value-added outputs.

A business process lays out the sequence of steps and decision points to perform a common and repeatable piece of work. Employee onboarding is a good example. The onboarding process defines:

- the sequence of work

- who is responsible for each step

- what they need to do

- the inputs, outputs suppliers and customers

- any supporting technology or tools

Processes can be an input or an output of other processes. For example, the HR Onboarding process may trigger processes in the finance, administration, or facilities department.

Understanding how processes interact with each other provides an end-to-end view of work in the company. Understanding this view is an essential step in reducing waste and improving business outcomes.

It’s important to note that a process is not a procedure.

A process guides the reader on “WHAT” to do, and “WHO” does it. Processes are cross-functional, and focused on business goals.

A procedure guides the reader on HOW to do it. It documents what tools to use along with step by step work instructions.

Process mapping is not to be confused with creating procedures!

Process Mapping Techniques

You cannot create a process map in isolation. You need to work with team members familiar with the execution of the process.

You need to bring together a subset of knowledgeable stakeholders involved in the process. That is because a substantial amount of work in an organization is never documented.

Getting cross-functional input into designing or improving a process is also important to foster buy-in and adoption.

Workshops are a typical way to begin the mapping of a business process.

These workshops should be led by a facilitator or project manager with excellent communication skills and experience in business process modeling. For example, someone with Six Sigma training.

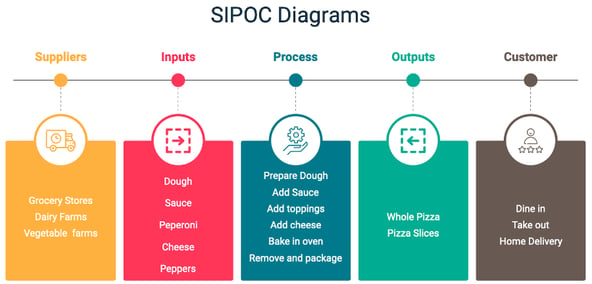

The process modeling workshop can start with reviewing the overall workflow of the process. This can be done using a SIPOC Diagram, or high-level process flows to guide the discussion. The use of a process mapping template, such as those available in the Navvia Process Designer, can also help accelerate the design process.

It's important to start at a high level and then drill down to deeper levels of detail in subsequent sessions. Always start with the big picture. Getting into the details too early causes you to lose sight of the overall objective.

The facilitator captures the process details. There are various tools that can help. These include a whiteboard, yellow stickies, or one of the many available process mapping tools, such as the Navvia Process Designer.

While mapping the process, the team should look for opportunities to improve process efficiency by reducing complexity or identifying automation opportunities.

Comprehensive business process mapping may require several workshops. Once mapped, the facilitator should validate the process with a broad cross-section of stakeholders.

Learn the 7 simple rules to design a process.

Process Mapping Examples

There are several different types of process maps. These include:

- Business Process Modelling Notation (BPMN)

- Line of Visibility Enterprise Modeling (LOVEM)

- Swimlane Diagrams

- Standard process flowcharting techniques

- Flow Process Chart

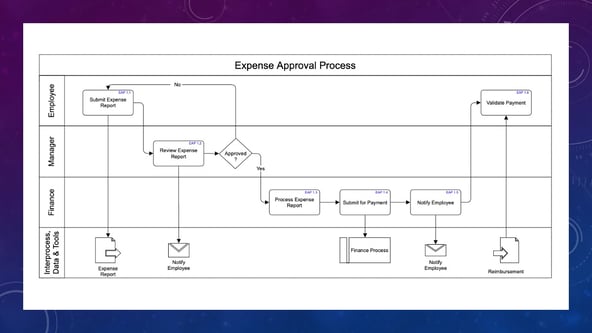

The following is an example of a simple swim lane process map for an expense approval process.

Sample Expense Approval Process

Sample Expense Approval Process

In a swimlane diagram, we create a lane for each role in the process. We place each task (or step) in the corresponding lane. This technique makes it very easy to see who is responsible for the task.

There may also be a dedicated lane that shows any data, systems used, or other processes referenced.

Line of Visibility Enterprise Modeling (LOVEM) is a type of swimlane diagram. The top swim lane is always used to represent the customer or end-user. This technique ensures that the focus is on supporting business outcomes, not on internal requirements.

Business Process Modeling Notation is another prevalent form of creating process maps. It is a potent tool that allows analysts to capture processes consistently.

Regardless of the process mapping method you choose, the goal should be to create concise, complete, and informative documents. To learn more about process diagrams check out this article: Process Diagrams: Why they are important & examples to get you started.

The Navvia Process Designer is a popular tool for process mapping. It offers a powerful design tool with out-of-the-box process templates for ITIL, COBIT, and ServiceNow® processes.

Process Capability

What is meant by process capability? Technically, it is a statistical tool to measure if your processes are deviating from desired outcomes. This method is critical when attempting to control heavily automated manufacturing processes.

In IT Service Management, we look at process capability as having all the right controls in place.

For example; is the process defined, does it have ownership, and is it being measured and improved?

ITSM Maturity Assessment Model

An ITSM Process Maturity Assessment can be used to assess process capability.

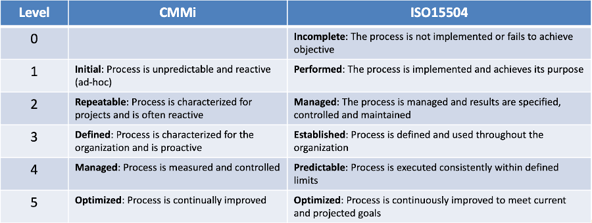

There are two popular methods for performing an ITSM process maturity assessment. The first is the Capability Maturity Model (CMMi) developed by Carnegie Mellon University and administered by ISACA.

The second is the international standard ISO/IEC 15504 (which has been superseded by ISO/IEC 33001).

Both measure capability on a scale of 0-5, with five being the most capable/mature. Here is a definition of the various levels.

An experienced assessor should conduct the process capability assessment.

Assessments consist of:

- Interviewing stakeholders

- Observing the processes in action

- Evaluating process tools and documentation

- Collecting data via standardized assessment questionnaires.

The assessor should validate their observations with stakeholders before compiling their findings and recommendations.

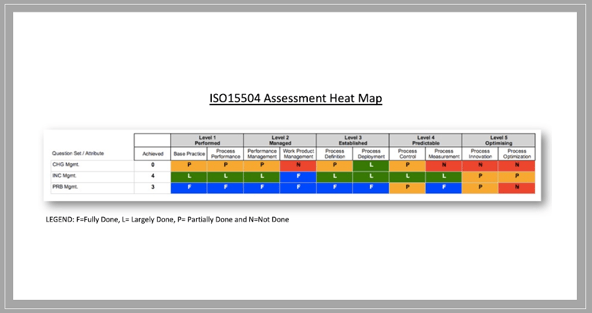

Assessors can use an ISO15505 heat map to share observations with stakeholders. Here is an example of a process capability heat map.

The heat map identifies areas where the process is deficient.

Think of a heat map like a series of hurdles. To move up a capability level, you need to be “largely” or “fully” compliant in the preceding level.

The assessor derives the score from a set of standardized questions.

The Navvia Process Designer offers a powerful assessment tool that utilizes the CMMi and ISO/IEC 15504 capability assessment models.

The Navvia Process Designer includes hundreds of out-of-the-box process assessment questionnaires for ITIL, COBIT, and ISO20000 processes.

Process Improvement

Defining and implementing a process is not a one-time affair.

Business requirements change over time, and business processes need to reflect those changes.

It is also essential to validate the business process is practical, efficient, and adds value to the organization.

Process improvement is a discipline focused on optimizing business processes through incremental improvements to process performance and end-user experience.

Process Improvement Techniques

There are various process improvement techniques available to the organization.

- Process capability assessments, discussed in the previous section, can help identify deficiencies and gaps in the processes.

- Process mapping is essential as you cannot improve a business process unless you understand it.

- SIPOC Diagrams are a great starting point for process improvement. A SIPOC Diagram identifies the suppliers, inputs, process, outputs, and customers of a business process, all on a single page. Here is an example of a SIPOC Diagram.

SIPOC Diagram Example

- Value Stream Mapping is a tool used to identify and eliminate waste in a process. Starting with a SIPOC Diagram, you decompose the process into its constituent steps. You then quantify the processing time and wait time for each step. The goal is to determine the cycle time for each step, then look for ways to improve.

- The Plan, Do, Check, and Act (PDCA) cycle. is a technique that calls for process improvement in every area of the business.

- Six Sigma is a set of process improvement techniques made famous by Jack Welch during his time at General Electric. A key component of Six Sigma is the DMAIC (Define, Measure, Analyze, Improve, and Control) cycle.

- LEAN Methodology is an approach designed to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources.

There are many tools and techniques available for process improvement, and it is perfectly acceptable to combine approaches from different disciplines.

Process improvement boils down to evaluating your processes’ effectiveness and implementing improvements based on changing business needs. Don't wait till your process fails, you need to constantly monitor and evaluate performance. You don't want to learn your disaster recovery process is broken in the middle of a disaster.

Business Process Management

This article discussed process mapping and the various techniques to assess, design, and improve processes.

Business Process Management (BPM) is the discipline that brings it all together into a repeatable practice.

Like any discipline, Business Process Management requires focus and governance. One way to achieve this is by creating a Business Process Office (BPO).

Effective BPM requires specific skill sets, skills not typically embedded in the business units.

Think of a Business Process Office as a “Swat Team” helping the business units design, improve, and implement their processes.

Business Process Management Skills

Skills can include:

- Business process analysts (process discovery and process mapping)

- Technical analysts (process implementation)

- Process assessment and governance

- Training

- Communications

- Organizational change management (OCM)

- Program management

Do you have a Service Management Office? Many of the SMO skills are directly transferable to Business Process Office. Learn more about how an SMO can drive digital transformation.

Process mapping and the overarching practice of Business Process Management are more important than ever before. Organizations, to deliver superior customer experiences, are embarking upon Digital Transformation initiatives. Processes are analogous to blueprints and are essential to building any successful Digital Transformation.